- Nederlands, Belgique / België

- Česky, Česká republika

- Deutsch, Deutschland

- Español, España

- English, Europe

- Français, France

- Italiano, Italia

- Magyar, Magyarország

- Nederlands, Nederland

- Deutsch, Österreich

- Polski, Polska

- Română, România

- Français / Deutsch, Suisse / Schweiz

- Svenska, Sverige

- Suomeksi, Suomi

- Türkçe, Türkiye

- English, United Kingdom

- Slovenská, Slovak

- Español, Mexico

- Összes Kézi mérőeszközök és adatátviteli rendszerek

- Adatkezelés

- Mikrométerek

- Furatmérők

- Tolómérők

- Mélységmérők

- Magasságmérők

- Mérőórák és Tapintókaros mérőórák

- Kiegészítő berendezések és egyéb tartozékok

- Kalibráló készülékek

- Mérőhasábok

- Összes Koordináta mérőgépek

- Mérőgépek kis- és közepes méréstartománnyal

- Gyártósorba integrálható mérőgépek (4)

- Mérőgépek nagy méréstartománnyal

- Mérőfejek, Szenzorok és Tapintók

- Styli

- Munkadarabrögzítő rendszer

- Készülékek, Konténerek

- Mérőgép szoftverek

- Összes Képfeldolgozó rendszerek

- Quick Image - manuális 2D képfeldolgozó rendszerek

- Quick Scope manuális / CNC képfeldolgozó rendszerek

- Quick Vision 3D CNC képfeldolgozó rendszerek

- Quick Vision 3D multiszenzoros mérőgépek

- 3D CNC Multisensor Measuring Machines MiSCAN

- 3D CNC mérőgép mikro-geometriai elemek mérésére

- Képfeldolgozó rendszer tartozékok

- Összes Optikai mérőgépek

- Nagyítók

- Mérőmikroszkópok

- Mikroszkóp egységek

- Szemlencsék és objekítvek

- Profilprojektorok

- TAGLENS

- M2 for Measuring Microscopes and Projectors

- Összes Alakvizsgáló berendezések

- Felületi érdességmérők Surftest

- Kontúrmérő berendezések Contracer

- Kombinált érdesség/kontúrmérő berendezések Formtracer

- Köralakmérő berendezések Roundtest

- Form Szoftver

- Összes Keménységmérő berendezések

- Hordozható keménységmérő

- Rockwell, Super-Rockwell, Brinell

- Vickers Hardness HV-Sorozat

- Keménység automatizálás

- Micro-Vickers keménység HM-Sorozat

- Hardness Testing Software

- Reference materials and indenters

- Adatkezelés

- Minőségirányítási rendszerek

- Digimatic adatprocesszor

- Jelkábelek

- Vezeték nélküli kommunikációs rendszer U-WAVE

- Digimatic interfészek

- Tűréseszközök, Időzítők, Kijelzők és Adatgyűjtők

- Mikrométerek

- Digimatic / mechanikus mikrométerek

- Mikrométer tartozékok

- Beépíthető mikrométerek

- Beépíthető mikrométer tartozékok

- Mérőórák és Tapintókaros mérőórák

- ABSOLUTE Digimatic mérőórák

- Analóg mérőórák

- Mérőóra tartozékok

- Szögtapintós mérőórák

- Szögtapintós mérőóra tartozékok

- Vastagságmérők, mélységmérők, rétegvastagség mérők

- Kiegészítő berendezések és egyéb tartozékok

- Mérőóra állványok

- Precíziós satuk

- Alaplapok és gránit síkok

- Szögmérők és szintezők

- Érzékelők, vonalzók, késélek

- Mérőhasábok

- Acél mérőhasáb készletek

- Acél egyedi mérőhasábok

- Kerámia mérőhasáb készletek

- Kerámia egyedi mérőhasábok

- Speciális mérőhasábok

- Mérőhasáb tartozékok

- Négyzet keresztmetszetű mérőhasáb tartozékok

- Mérőgépek kis- és közepes méréstartománnyal

- CRYSTA-APEX S 500,700 és 900-as sorozat

- CRYSTA-Apex V1200, 1600 & 2000 Series

- CRYSTA-Apex EX1200R Series

- STRATO-Active Sorozat

- STRATO-APEX 500, 700 és 900-as sorozat

- STARTO-APEX 1600-as sorozat

- LEGEX sorozat (4)

- Mérőfejek, Szenzorok és Tapintók

- SurfaceMeasure

- REVO

- Szkennelő mérőfejek

- Hagyományos tapintós szenzorok

- PH20

- Styli

- Styli Kits

- Straight Styli

- Diamond Coated Styli

- Master Ball

- Machine Tool Styli

- Star Styli

- Styli for Star Styli

- Cylinder Styli

- Disk Styli

- Tip Styli

- Extensions

- Holders

- Adapters

- Joints

- Screws for Cubes

- Tools

- StyliCleaner

- Munkadarabrögzítő rendszer

- CMM Fixturing Kits

- eco-fix pallet receiver system PRS

- FixtureBuilder Software for eco-fix

- FMI Fixturing Kits

- eco-fix and eco-fixplus Extension Sets

- eco-fix and eco-fixplus Components

- Screws and Tools (17) for eco-fix, eco-fixplus

- opti-fix Fixturing Kits for Optical Measurement

- opti-fix Components

- Mérőgép szoftverek

- MiCAT Planner

- MCOSMOS - Moduláris szoftver teljeskörű mérésekre

- MAFIS-Express - Gyors turbinalapát mérő szoftver

- MSURF-S és MSURF-I dedikált vonal lézer szkenner mérés a Mitutoyo Surface Measure sorozathoz.

- Quick Scope manuális / CNC képfeldolgozó rendszerek

- Manuális Quick Scope QS-L sorozat

- Quick Scope szoftver

- Quick Vision 3D CNC képfeldolgozó rendszerek

- Quick Vision ACTIVE

- Quick Vision APEX / HYPER sorozat

- Quick Vision ACCEL sorozat

- Quick Vision ULTRA

- Quick Vision 3D multiszenzoros mérőgépek

- Quick Vision HYBRID Típus 4

- Quick Vision White Light Interferometer

- Mérőmikroszkópok

- TM-500 mérőmikroszkóp B-generáció

- Standard Measuring Microscopes MF Series (13) Manual MF-A/B Models and Motor-Driven Z-axis MF-J Models

- Universal Measuring Microscopes MF-U Series Manual MF-UA/UB/UC/UD Models and Motor-Driven Z-axis MF-UJ/UK Models

- Opcionális fényforrás MF/MF-U D-generáció mérőmikroszkóphoz

- Hyper MF / MF-U mérőmikroszkóp B-generáció

- Vision Unit

- Microscope Cameras

- Szemlencsék és objekítvek

- Véges korrigált ML-sorozatú objektívek

- Objetívek világos mező megfigyelésre FS-sorozat

- Objetívek világos/sötét mező megfigyelésre FS-sorozat

- Objectives for NIR

- Objectives for NIR LCD

- Objectives for NUV

- Objectives for NUV LCD

- Objectives for UV

- Objectives for UV LCD

- Profilprojektorok

- PJ Sorozat

- PV Sorozat

- PH Sorozat

- M2 Software

- Data Processing Unit

- QM-Data 200 adatfeldolgozó egység

- Profilprojektor tartozékok

- Felületi érdességmérők Surftest

- Surftest SJ-210

- Surftest SJ-310

- Surftest SJ-410

- Surftest SJ-500

- Surftest SJ-500P

- Surftest SV-2100P

- Formtracer Avant FTA-S3000

- Surftest Extreme SV-3000CNC

- Surftest Extreme SV-M3000CNC

- Kombinált érdesség/kontúrmérő berendezések Formtracer

- Formtracer Avant FTA-D3000 / FTA-D4000 Series

- Formtracer CS-3300

- Formtracer Extreme SV-C4500CNC

- Formtracer Extreme SV-C4500CNC HYBRID Type 1

- Formtracer Extreme CS-5000CNC and CS-H5000CNC

- Hordozható keménységmérő

- Ütés elven alapuló keménységmérés: HARDMATIC HH-411

- Digitális és analóg Durometer: HARDMATIC HH-300

- Rockwell, Super-Rockwell, Brinell

- Rockwell HR-100/200/300/400

- Wizhard Rockwell, Super-Rockwell, Brinell keménységmérő: HR-500 sorozat

- Rockwell Automatic Hardness Testing HR-600

- Keménység automatizálás

- Automatic Micro-Vickers hardness testing systems

- Automatic Vickers hardness testing systems

- Reference materials and indenters

- Hardness reference materials

- Hardness indenters and replacement balls

- Linear Gauges

- ABSOLUTE Digimatic Linear Gauge LGS Series

- Air Drive Unit

- Standard Linear Gauge LGF Series

- Linear Gauge LG100 Series

- Linear Gauge LG200 Series

- Laser Hologauge

- Counters and Display Units

- EJ Counter and Interfaces for Linear Gauges

- EC Counter for Linear Gauges

- EG Counter for Linear Gauges

- EB Counter for Linear Gauges

- EH Counter for Linear Gauges

- EV Counter for Linear Gauges

- Display Unit for EV Counter

- Laser Scan Micrometers

- Laser Scan Micrometer Measuring Unit and Display Unit Package

- Laser Scan Micrometer Measuring Unit

- Laser Scan Micrometer

- Laser Scan Micrometer Display Unit

- Laser Scan Micrometer Optional Accessories

- DRO Linear Scales and Counters

- DRO Linear Scales AT103

- DRO Linear Scales AT103 - High Accuracy

- DRO Linear Scales AT113

- DRO Linear Scales AT113 - High Accuracy

- DRO Linear Scales AT116

- DRO ABS Linear Scales AT715

- Universal DRO KA-200 Counter

- NC Linear Scales

- NC Linear Scales ST36

- NC Linear Scales ST46-EZA

- NC Linear Scales ABS ST700

- NC Linear Scales ABS ST1300

- NC Linear Scales AT211

- NC Linear Scales ABS AT1100

- NC Linear Scales ABS AT1300

- Scale Units

- Horizontal ABSOLUTE Scale Coolant Proof IP66

- Horizontal ABSOLUTE Scale Standard

- Horizontal ABSOLUTE Scale Measurement Direction Switching

- Horizontal ABSOLUTE Scale Diameter Function

- Vertical ABSOLUTE Scale Standard

- Vertical ABSOLUTE Scale Measurement Direction Switching

- Vertical ABSOLUTE Scale Diameter Function

Repülőgépipar

Repülőgépipar

Az összetett repülési alkalmazások gyors, rendkívül precíz minőségellenőrzést igényelnek a pontos összeszerelés érdekében. Nézze meg, hogyan valósítja meg a Mitutoyo

Autóipar

Autóipar

Az autóipar folytatja az innovációt, és a Mitutoyo fejlett ellenőrzési és szkennelési képességekkel segíti a gyártókat a folyamatos termelés elérésében.

Energiaipar

Energiaipar

A Mitutoyo mérési és elemzési megoldásait úgy tervezték, hogy segítsék az energiaszolgáltatókat a megbízhatóság javításában és a berendezések üzemidejének növelésében.

Gyógyszeripar

Gyógyszeripar

A betegek jólétének védelme érdekében az orvosi alkalmazások kivételes pontosságot igényelnek. Tekintse meg, hogy a Mitutoyo széles körben tesztelt megoldásai hogyan segíthetik ezt elérni.

Általános gépipar

Általános gépipar

Biztosítsa a magas ismételhetőséget és a szigorú minőségellenőrzést a Mitutoyo alakmérési megoldásaival, koordináta mérőgépeivel és precíziós mérőeszközeivel.

Elektronikaipar

Elektronikaipar

A Mitutoyo érintésmentes és optikai mérési megoldásai mikroszkopikus pontosságot biztosítanak a kisebb és sűrűbb elektronikus alkatrészek számára

Original Equipment Manufacturers (OEM)

Original Equipment Manufacturers (OEM)

A Mitutoyo OEM úgy tudja kezelni a hiányzó szakértelmet vagy erőforrásokat, hogy olyan híres metrológiai berendezéseinket szállítja Önnek, amelyek zökkenőmentesen integrálhatók termékeibe.

Esettanulmányok

Esettanulmányok

A Mitutoyo képességeinek áttekintéséhez ez nem jobb hely, mint csodálatos esettanulmány-gyűjteményünk.

Mitutoyo Japan ügyfélkezelés

Mitutoyo Japan ügyfélkezelés

Az Európában működő japán cégek első állomása.

Egyedi termékek

Egyedi termékek

Egyedi termékek egyedi alkalmazásokhoz

Gyártásautomatizálási megoldások

Gyártásautomatizálási megoldások

Varázsolja gyárát intelligens gyárrá a Mitutoyo segítségével

Mitutoyo rendszer integrátorok

Mitutoyo rendszer integrátorok

A mérőeszközök integrálása a meglévő folyamatokba egyszerűvé vált

Javítás és Pótalkatrészek

Javítás és Pótalkatrészek

Alkatrészek és javítások Mitutoyo készülékekhez

Kalibrálás

Kalibrálás

Kalibrálja mérőeszközeit egy megbízható laboratóriumban

Helyszíni szolgáltatások

Helyszíni szolgáltatások

Kedvenc mérő- és vizsgálógépeinek helyszíni szervize

Mérési szolgáltatások

Mérési szolgáltatások

Mérje meg munkadarabjait és alkatrészeit bárhol Európában

Termékbemutatók

Termékbemutatók

Online vagy offline, vegyen részt termékbemutatón még ma

IT támogatás

IT támogatás

Tökéletes és problémamentes telepítés és integráció az IT infrastruktúrába.

Oktatási csomag

Oktatási csomag

Tökéletes műhelybe vagy tanterembe, nincs nagyobb segítség, mint a Mitutoyo plakátjai vagy tananyagai.

E-Learning

E-Learning

A metrológia iránt érdeklődők számára a Mitutoyo e-Learning kurzusokat kínál a diákok, a személyzet vagy akár a hobbisták képzéséhez.

Online média

Online média

Ha gyorsan szeretne többet megtudni a mérésről, tekintse meg számos oktatóvideónkat.

Fedezze fel a Mitutoyo-t

Fedezze fel a Mitutoyo-t

A világ legnagyobb metrológiai vállalata

Kereskedelmi termékek

Kereskedelmi termékek

Azok, akik stílusosan szeretnének bejárni a boltot, menjenek az áruboltba, és támogassák kedvenc márkájukat.

Karrier

Karrier

Itt többet megtudhat arról, milyen érzés a Mitutoyónál dolgozni és a karrierje megkezdésének következő lépéseiről.

Termék prospektusok

Termék prospektusok

Tekintse meg és töltse le katalógusunkat, termékprospektusainkat és egyebeket.

Szoftverek

Szoftverek

Töltse le szoftvereinket és frissítéseinket egyszerűen és kényelmesen

Megfelelőségi nyilatkozatok

Megfelelőségi nyilatkozatok

Itt letöltheti az EU és az Egyesült Királyság teljes verzióját.

Háttérképek

Háttérképek

Töltse le ingyen a hivatalos Mitutoyo háttérképeket.

Mitutoyo márka kommunikációs anyagok

Mitutoyo márka kommunikációs anyagok

Erőforrások a Mitutoyo munkatársai és külső beszállítók számára.

Online katalógus

Online katalógus

Tekintse meg széles termékkínálatunkat online katalógusunkban!

-

Termékek

- Vissza Termékek

- Termékek

-

Kézi mérőeszközök és adatátviteli rendszerek

- Vissza Kézi mérőeszközök és adatátviteli rendszerek Összes Kézi mérőeszközök és adatátviteli rendszerek

- Adatkezelés

- Mikrométerek

- Furatmérők

- Tolómérők

- Mélységmérők

- Magasságmérők

- Mérőórák és Tapintókaros mérőórák

-

Kiegészítő berendezések és egyéb tartozékok

- Vissza Kiegészítő berendezések és egyéb tartozékok Kiegészítő berendezések és egyéb tartozékok

-

Mérőóra állványok

-

Precíziós satuk

-

Alaplapok és gránit síkok

-

Szögmérők és szintezők

-

Érzékelők, vonalzók, késélek

-

Kalibráló készülékek

- Vissza Kalibráló készülékek Kalibráló készülékek

-

Height Master

-

Check Masterek

-

Kalibráló eszközök

- Mérőhasábok

-

Koordináta mérőgépek

- Vissza Koordináta mérőgépek Összes Koordináta mérőgépek

-

Mérőgépek kis- és közepes méréstartománnyal

- Vissza Mérőgépek kis- és közepes méréstartománnyal Mérőgépek kis- és közepes méréstartománnyal

- CRYSTA-APEX S 500,700 és 900-as sorozat

- CRYSTA-Apex V1200, 1600 & 2000 Series

- CRYSTA-Apex EX1200R Series

- STRATO-Active Sorozat

- STRATO-APEX 500, 700 és 900-as sorozat

- STARTO-APEX 1600-as sorozat

- LEGEX sorozat (4)

-

Gyártósorba integrálható mérőgépek (4)

- Vissza Gyártósorba integrálható mérőgépek (4) Gyártósorba integrálható mérőgépek (4)

- MACH KO-GA-ME sorozat

- MiSTAR 555

- MACH 3A 653

- MACH V 9106

-

Mérőgépek nagy méréstartománnyal

- Vissza Mérőgépek nagy méréstartománnyal Mérőgépek nagy méréstartománnyal

- CARB-Strato / CARB-Apex sorozat

-

Mérőfejek, Szenzorok és Tapintók

- Vissza Mérőfejek, Szenzorok és Tapintók Mérőfejek, Szenzorok és Tapintók

- SurfaceMeasure

- REVO

- Szkennelő mérőfejek

- Hagyományos tapintós szenzorok

- PH20

- Styli

-

Munkadarabrögzítő rendszer

- Vissza Munkadarabrögzítő rendszer Munkadarabrögzítő rendszer

-

CMM Fixturing Kits

- eco-fix pallet receiver system PRS

- FixtureBuilder Software for eco-fix

- FMI Fixturing Kits

- eco-fix and eco-fixplus Extension Sets

-

eco-fix and eco-fixplus Components

- Screws and Tools (17) for eco-fix, eco-fixplus

- opti-fix Fixturing Kits for Optical Measurement

-

opti-fix Components

-

Készülékek, Konténerek

- Vissza Készülékek, Konténerek Készülékek, Konténerek

- Mérőgép védőkabinok

- Mérőgép szoftverek

-

Képfeldolgozó rendszerek

- Vissza Képfeldolgozó rendszerek Összes Képfeldolgozó rendszerek

-

Quick Image - manuális 2D képfeldolgozó rendszerek

- Vissza Quick Image - manuális 2D képfeldolgozó rendszerek Quick Image - manuális 2D képfeldolgozó rendszerek

- Quick Image

- Quick Image szoftver

-

Quick Scope manuális / CNC képfeldolgozó rendszerek

- Vissza Quick Scope manuális / CNC képfeldolgozó rendszerek Quick Scope manuális / CNC képfeldolgozó rendszerek

- Manuális Quick Scope QS-L sorozat

- Quick Scope szoftver

-

Quick Vision 3D CNC képfeldolgozó rendszerek

- Vissza Quick Vision 3D CNC képfeldolgozó rendszerek Quick Vision 3D CNC képfeldolgozó rendszerek

- Quick Vision ACTIVE

- Quick Vision APEX / HYPER sorozat

- Quick Vision ACCEL sorozat

- Quick Vision ULTRA

-

Quick Vision 3D multiszenzoros mérőgépek

- Vissza Quick Vision 3D multiszenzoros mérőgépek Quick Vision 3D multiszenzoros mérőgépek

- Quick Vision HYBRID Típus 4

- Quick Vision White Light Interferometer

-

3D CNC Multisensor Measuring Machines MiSCAN

- Vissza 3D CNC Multisensor Measuring Machines MiSCAN 3D CNC Multisensor Measuring Machines MiSCAN

- MiSCAN APEX 404

- MiSCAN HYPER 302

- MiSCAN HYPER 404

-

3D CNC mérőgép mikro-geometriai elemek mérésére

- Vissza 3D CNC mérőgép mikro-geometriai elemek mérésére 3D CNC mérőgép mikro-geometriai elemek mérésére

- UMAP rendszer

- UMAP Software

-

Képfeldolgozó rendszer tartozékok

- Vissza Képfeldolgozó rendszer tartozékok Képfeldolgozó rendszer tartozékok

-

Objektívek és kalibráló lapok

- QV Index

-

Optikai mérőgépek

- Vissza Optikai mérőgépek Összes Optikai mérőgépek

- Nagyítók

-

Mérőmikroszkópok

- Vissza Mérőmikroszkópok Mérőmikroszkópok

-

TM-500 mérőmikroszkóp B-generáció

-

Standard Measuring Microscopes MF Series (13) Manual MF-A/B Models and Motor-Driven Z-axis MF-J Models

-

Universal Measuring Microscopes MF-U Series Manual MF-UA/UB/UC/UD Models and Motor-Driven Z-axis MF-UJ/UK Models

- Opcionális fényforrás MF/MF-U D-generáció mérőmikroszkóphoz

- Hyper MF / MF-U mérőmikroszkóp B-generáció

-

Vision Unit

- Microscope Cameras

-

Mikroszkóp egységek

- Vissza Mikroszkóp egységek Mikroszkóp egységek

- FS-70 mikroszkóp egység

-

VMU videómikroszkóp egység

-

Szemlencsék és objekítvek

- Vissza Szemlencsék és objekítvek Szemlencsék és objekítvek

- Véges korrigált ML-sorozatú objektívek

-

Objetívek világos mező megfigyelésre FS-sorozat

- Objetívek világos/sötét mező megfigyelésre FS-sorozat

-

Objectives for NIR

- Objectives for NIR LCD

- Objectives for NUV

- Objectives for NUV LCD

- Objectives for UV

- Objectives for UV LCD

- Profilprojektorok

- TAGLENS

- M2 for Measuring Microscopes and Projectors

-

Alakvizsgáló berendezések

- Vissza Alakvizsgáló berendezések Összes Alakvizsgáló berendezések

- Felületi érdességmérők Surftest

-

Kontúrmérő berendezések Contracer

- Vissza Kontúrmérő berendezések Contracer Kontúrmérő berendezések Contracer

- Contracer CV-2100

-

Formtracer Avant FTA-C3000 and FTA-C4000

-

Kombinált érdesség/kontúrmérő berendezések Formtracer

- Vissza Kombinált érdesség/kontúrmérő berendezések Formtracer Kombinált érdesség/kontúrmérő berendezések Formtracer

-

Formtracer Avant FTA-D3000 / FTA-D4000 Series

- Formtracer CS-3300

- Formtracer Extreme SV-C4500CNC

- Formtracer Extreme SV-C4500CNC HYBRID Type 1

- Formtracer Extreme CS-5000CNC and CS-H5000CNC

-

Köralakmérő berendezések Roundtest

- Vissza Köralakmérő berendezések Roundtest Köralakmérő berendezések Roundtest

-

Roundtest

- Roundtracer Extreme

- Roundtracer FLASH

-

Form Szoftver

- Vissza Form Szoftver Form Szoftver

-

Formtracepak

-

Roundpak

-

Keménységmérő berendezések

- Vissza Keménységmérő berendezések Összes Keménységmérő berendezések

- Hordozható keménységmérő

- Rockwell, Super-Rockwell, Brinell

-

Vickers Hardness HV-Sorozat

- Vissza Vickers Hardness HV-Sorozat Vickers Hardness HV-Sorozat

- Vickers Keménységmérő HV-110/120

- Keménység automatizálás

-

Micro-Vickers keménység HM-Sorozat

- Vissza Micro-Vickers keménység HM-Sorozat Micro-Vickers keménység HM-Sorozat

- Mikro-Vickers keménységmérő: HM-210/220

-

Hardness Testing Software

- Vissza Hardness Testing Software Hardness Testing Software

- AVPAK

-

Reference materials and indenters

- Vissza Reference materials and indenters Reference materials and indenters

-

Hardness reference materials

-

Hardness indenters and replacement balls

- Elmozdulás mérők

-

Lineáris útmérők és tartozékok

- Vissza Lineáris útmérők és tartozékok Összes Lineáris útmérők és tartozékok

- DRO Linear Scales and Counters

- NC Linear Scales

-

Scale Units

- Vissza Scale Units Scale Units

- Horizontal ABSOLUTE Scale Coolant Proof IP66

- Horizontal ABSOLUTE Scale Standard

- Horizontal ABSOLUTE Scale Measurement Direction Switching

- Horizontal ABSOLUTE Scale Diameter Function

- Vertical ABSOLUTE Scale Standard

- Vertical ABSOLUTE Scale Measurement Direction Switching

- Vertical ABSOLUTE Scale Diameter Function

- Iparágak

-

Szolgáltatások

- Vissza Szolgáltatások

- Szolgáltatások

- Mitutoyo Japan ügyfélkezelés

-

Okos gyár (Smart Factory) megoldások

- Vissza Okos gyár (Smart Factory) megoldások

- Okos gyár (Smart Factory) megoldások

- Egyedi termékek

- Gyártásautomatizálási megoldások

- Mitutoyo rendszer integrátorok

- Javítás és Pótalkatrészek

- Kalibrálás

- Helyszíni szolgáltatások

- Mérési szolgáltatások

-

Metrológiai és Termékoktatások

- Vissza Metrológiai és Termékoktatások

- Metrológiai és Termékoktatások

- Termékbemutatók

- IT támogatás

- Oktatás

- A Mitutoyo-ról

- Hírek

- Letöltések

- Helpdesk*

Győződjön meg arról, hogy központja folyamatosan csatlakoztatható, és növelje a mérési hatékonyságot a tervezés és a mérés összekapcsolásával. A termelési szint mérési adatainak valós idejű összekapcsolása összekapcsolja a termelést és a mérést, hogy jobban látható legyen a minőség. A mérési IoT megváltoztatja a vállalatát.

TERVEZÉS ÉS MÉRÉS ÖSSZEFÜGGÉSE

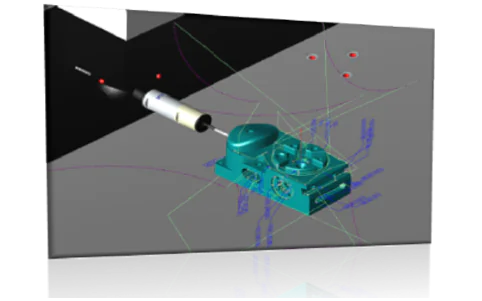

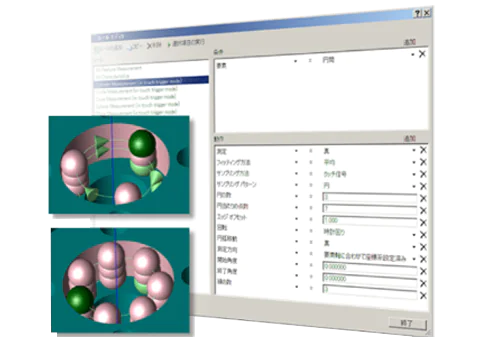

A mérési műveletek hatékonyságának növelése érdekében alaposan vizsgálja meg a tervezési folyamatot. Csak a toleranciainformációk hozzáadásával a 3D CAD modellekhez "egy kattintással"

mérési modellek generálása a "MiCAT Planner" segítségével lehetséges. Takarítson meg akár 95 százalékos időt az úttörő CMM mérőprogram-generáló szoftverünkkel.

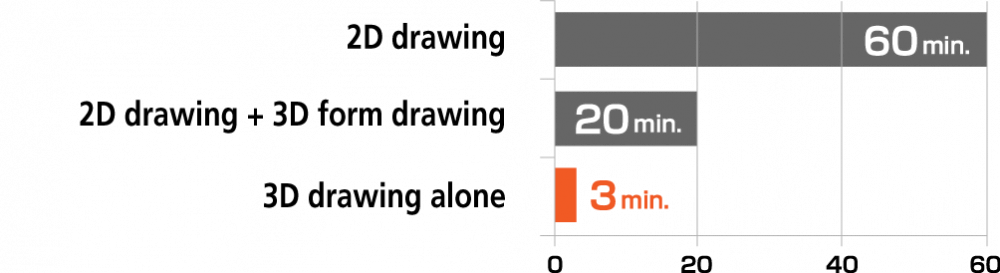

A mérési program előkészítési ideje akár 95%-kal csökkentve

Ami a hagyományos "2D diagram" manuális módszerrel 45-60 percet vett igénybe, a "2D diagram + 3D CAD" módszerrel pedig 15-20 percet vett igénybe, most körülbelül 3 perc alatt elvégezhető a MiCAT Planner segítségével.

Mintablokk mérési rész program előkészítési idő összehasonlítása

Automatically optimized measurement path

Measurement in the Quickest Time Possible; a Dramatic Increase in Measurement Operation Efficiency

What took 45 to 60 minutes with a traditional "2D diagram" method manually and 15 to 20 minutes with a "2D diagram + 3D CAD file" method, can now be completed in approximately 3 minutes using MiCAT Planner.

Using optimization functions, the smallest number of probe-position and tool changes and the shortest measurement path is determined by the software, and a program is generated for the measurement in the minimum amount of time.

By shortening measurement time, large measurement operation efficiency gains are possible!

Stable Measurement Quality With No Variations Between Workers

By defining measurement rules using the rules editor function, you can automatically generate a measurement path conforming to those rules. This prevents quality variations between programmers.

Also, you can automatically generate a measurement path conforming to those rules, so there are no variations between programmers.

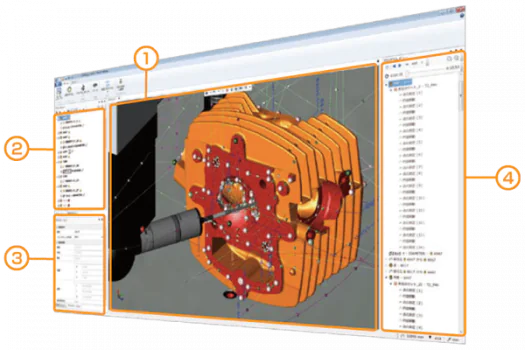

Screen configuration and functions

Intuitive operations; easy-to-use simple view

The MiCAT Planner screen configuration provides a "simple view" configuration that enables intuitive operations (3D view, plan view, etc.). You can also freely customize positioning and window size.

| ① 3D view | Graphical information is displayed. ・Measuring device information ・CAD models, tolerance information ・Measuring points, measurement path ・Measuring animation |

| ② Plan view | ・Display list of measuring elements, tolerances, etc. ・The existence of measurement and evaluation can be selected using a check box. |

| ③ Property view | Element, tolerance, and measuring point name changes and measuring point editing can be done for each individual element. |

| ④ Program view | ・Display measurement details and projected measurement times. ・Using the animation function, it is possible to execute a 3D-view measurement animation. |

| CAD formats | Extension | Supported versions |

|---|---|---|

| ACIS | .sat | R1-2016.1.0 (PMI not supported) |

| STEP | .step/ .stp | AP203, AP204, AP242 (PMI not supported) |

| NX *1 | .prt | 11-18, NX1-10 |

| Creo Parametric (Pro/E) *1 | .prt/ .prt.* | 16-Wildfire5, Creo 1.0-3.0 |

| CATIA v5 *1 | .CATPART | v5 R8 – 5 – 6R2016 |

| Solid Works *1 | .sldprt | 98 - 2016 (with PMI: 2014 - 2016) |

*1 Option (One of the types is included as standard.)

Note: The model needs to be a solid model. Assembly data not supported.

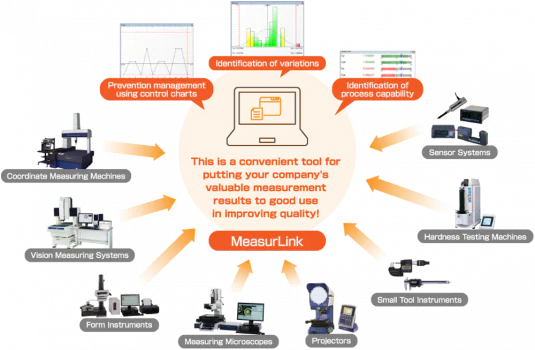

LINKING PRODUCTION AND MANAGEMENT

Using production floor data, build SPC (statistical process control) so that only good-quality products are produced. The "MeasurLink" measurement data network system gathers data from various types of measuring equipment and generates real-time displays of the results of statistical processing (control charts, histograms, process capability indexes, etc.).

The result is SPC.

Prevent scrap; produce only good-quality products

Gather real-time data from all network-connected measuring devices and then forecast defect occurrence using statistical process control.

Put your company's valuable measurement results to good use in improving quality. The quality of tomorrow's products can be known today.

Diverse and Easy-To-Use Data Collection Screens

Extensive Statistical Analysis Function Support (Xbar-R Control Charts, Run Charts, etc.)

Using the diverse range of statistical analysis and display functions, you can obtain results applicable to your particular situation and objectives

Alarm Function Warns Operators of Abnormalities

A warning is sent to the operator when abnormalities (Out of Tolerance, Out of Control Limit) occur. The warning method can be selected as a pop-up window display, email notification, log file entry, etc.

LINKING MANAGEMENT AND MEASUREMENT

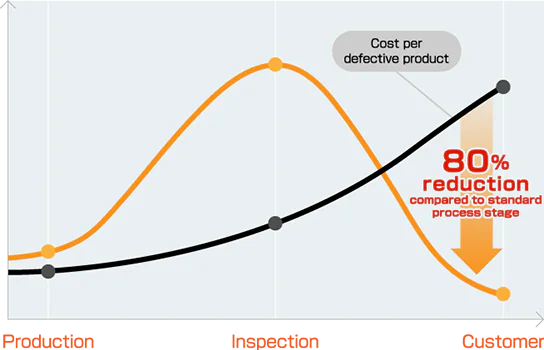

In-line measurement enables 100% inspection and centralized management. The resulting earlier discovery of defective products enables faster countermeasures and rework cost reductions, with the end result being an increase in profit.

Early Discovery of Defective Products

The MACH-3A makes it possible to discover defective products at an early stage in the production process.

Installation of the "MACH-3A" 3D measuring device makes it possible to discover defective products at an early stage in the production process. Through the early discovery of defective products, you can hold down the costs that such products generate.

Raise to 80% the percentage for "defective product discovery" in the production process stage.

MeasurLink, MiCAT Planner, and Smart Factories

It is clear that manufacturing industry process control is extremely important, not only for the production floor but also for corporate management.

In a Smart Factory, all equipment in the factory is connected to the Internet, and a diverse range of information is collected, analyzed, and managed so it can be put to good use on the production floor and in corporate management.

Through the installation of MeasurLink and MiCAT Planner, you can take a step forward in the realization of a Smart Factory.

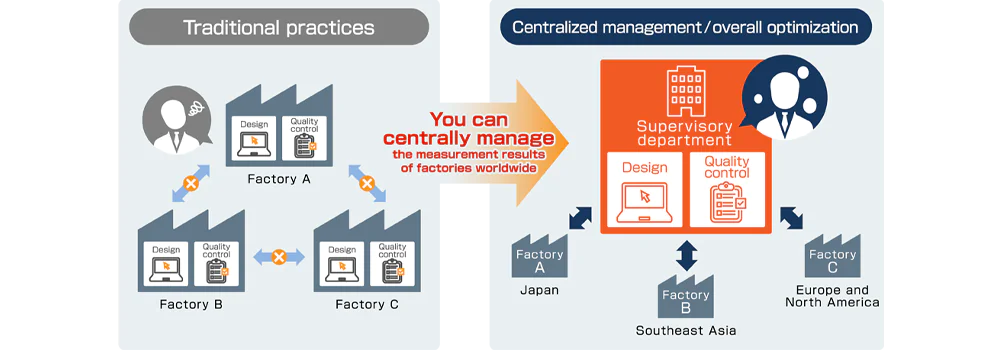

LINKING THE WORLD AND MEASUREMENT

Headquarters in the home country can be continuously connected via a network to factories dotting the globe. As market globalization progresses, connections between sites are expanding to a worldwide scale in the manufacturing industry. This is truly an era in which quality must be sustained at factories throughout the world.

Global Control of Quality Assurance Data

An increasing number of companies have factories overseas, primarily in Asia, and this includes not only huge enterprises but also medium- and small-sized firms. So it is important to produce products at a high-quality level at factories across the globe. By installing MeasurLink, you can perform centralized management of the measurement results of factories everywhere and achieve quality increases globally.